Ever wondered why some bearings fail quickly? TC Bearing performance matters in harsh conditions. Durability, load capacity, and long service life are key. In this article, you will learn how sintering, design, and materials improve TC Bearings. We discuss optimizing load, extending service life, and enhancing efficiency.

The Sintering Process of TC Bearings

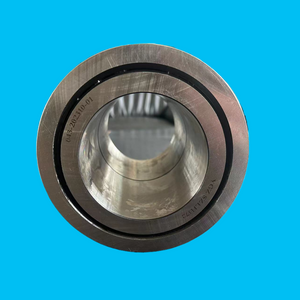

Fundamentals of TC Bearing Sintering

Sintering is the core process that defines the durability of TC Bearings. It involves fusing tungsten carbide particles under high temperature and pressure to form a dense, wear-resistant layer. This layer resists abrasive wear and erosion, ensuring long-term reliability even under heavy loads. The resulting microstructure significantly reduces the likelihood of cracks or weak spots that can compromise bearing performance.

During the sintering process, careful control of temperature and pressure determines the balance between hardness and toughness. High hardness increases wear resistance, while adequate toughness prevents brittle failure under dynamic stress. By fine-tuning these parameters, manufacturers create TC Bearings that consistently meet high operational demands.

Table 1: Key Sintering Parameters and Effects

Parameter | Effect on TC Bearings | Optimal Outcome |

Temperature | Influences hardness and density | Balanced toughness and wear resistance |

Pressure | Determines particle bonding strength | Uniform carbide layer |

Duration | Controls microstructural uniformity | Reduced weak spots, enhanced reliability |

Advanced Sintering Techniques

Modern manufacturing employs several advanced techniques to optimize the sintering process. Vibration filling ensures uniform distribution of carbide particles, while furnace brazing enhances bonding and coverage. Manufacturers also experiment with pellet versus strip methods to maximize material density and surface hardness. Each technique impacts the final microstructure and determines wear resistance and operational reliability.

These approaches allow engineers to produce Durability improvements in TC bearings, which are essential for high-stress environments. Vibration filling, for example, minimizes voids and ensures even particle packing, while brazing strengthens the interface between carbide and steel substrate. Combining these methods enhances both load capacity and service life.

Microstructural Benefits

A uniform carbide layer is crucial for predictable bearing performance. Any inconsistencies or weak spots can lead to premature wear or failure. By optimizing microstructure, manufacturers eliminate these weak points, resulting in reliable bearings capable of sustaining heavy radial and axial loads. Microstructural uniformity also improves resistance to thermal cycling, critical for high-speed machinery.

Sintering Process Optimization

Optimizing sintering involves adjusting temperature, pressure, and duration for the best compromise between hardness and toughness. Overheating can cause brittleness, while insufficient heat reduces density and wear resistance. Proper optimization ensures Enhanced load capacity TC bearings that can operate continuously under challenging conditions without degradation.

Load Capacity Enhancement in TC Bearings

Understanding Load Distribution

TC Bearings are designed to manage both radial and axial loads efficiently. Uneven load distribution can cause localized stress and early failure. Advanced design features, including the shape and placement of carbide inlays, help spread the load evenly across the bearing surface. This ensures that Enhanced load capacity TC bearings maintain their integrity under demanding operational conditions.

Bearing Design Innovations

Innovations in insert geometry, such as hexagonal versus round button-style inserts, significantly impact stress concentration. Hexagonal inserts distribute stress more evenly, reducing localized wear, while round inserts can offer smoother rotational characteristics. The extent of insert coverage also plays a critical role in maximizing load capacity and bearing longevity.

Table 2: Insert Geometry Effects on Load Capacity

Material Properties and Load Performance

The hardness, density, and bonding quality of TC materials dictate their dynamic load rating. High-density tungsten carbide provides excellent wear resistance, while strong bonding to the steel substrate ensures stability under vibration and shock. These material attributes are fundamental to achieving both Enhanced load capacity TC bearings and prolonged service life.

Application-Specific Load Considerations

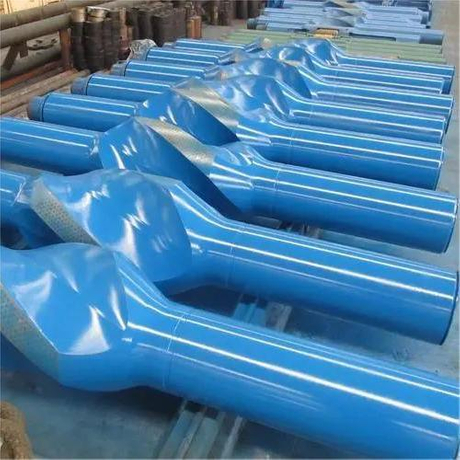

In downhole drilling and high-speed industrial motors, selecting the right TC Bearing configuration is essential. Radial load requirements vary by application, and bearing design must accommodate specific stresses and environmental challenges. For instance, bearings in drilling motors must withstand high radial loads, abrasive fluids, and rotational stresses simultaneously.

Service Life Optimization

Wear Resistance Factors

Material hardness directly affects erosion and abrasive wear resistance. TC Bearings with hardness around 70 HRC demonstrate significant improvements in resisting high-speed wear. Surface coatings and carbide inlays further enhance durability, protecting the core structure from premature degradation.

Lubrication Strategies

Effective lubrication is crucial for reducing friction and extending service life. Some TC Bearings utilize self-lubricating designs, eliminating the need for external lubricants, while others rely on precision-applied oils or greases. Proper lubrication management ensures minimal heat generation, reducing the risk of thermal damage and bearing seizure.

Environmental Challenges

TC Bearings often operate in high-temperature, high-pressure, or corrosive environments. Protective design features, such as sealed housings and corrosion-resistant coatings, mitigate the impact of these harsh conditions. Bearings engineered for environmental resilience demonstrate lower wear rates and longer operational life.

Maintenance and Downtime Reduction

Enhanced TC Bearing durability enables predictive maintenance strategies. Monitoring bearing condition and replacing components proactively reduces unplanned downtime. Over time, this translates into substantial cost savings and operational efficiency gains, reinforcing the value of investing in high-quality TC Bearings.

TIP:Proactive maintenance combined with durable TC Bearings significantly lowers the total cost of ownership and ensures uninterrupted production.

![TC Bearing TC Bearing]()

Comparative Analysis of TC Bearings

TC vs. Polycrystalline Diamond Compact (PDC) Bearings

While PDC Bearings offer exceptional hardness, TC Bearings provide a more balanced combination of hardness, toughness, and cost-effectiveness. TC Bearings excel in environments requiring high load capacity without the extreme cost associated with PDC.

Alternative Alloy Bearings

Compared to steel and other carbide alloys, TC Bearings outperform in both load capacity and service life. Their superior material properties reduce wear, enhance reliability, and offer better operational efficiency under high-stress conditions.

ROI and Lifecycle Assessment

The initial investment in TC Bearings may be higher than conventional bearings, but the extended service life and reduced maintenance translate into a strong return on investment. Lifecycle analysis consistently demonstrates that Extended service life of TC bearings offsets upfront costs, especially in demanding applications.

Design Considerations for High-Performance TC Bearings

Insert Geometry and Layout

Properly engineered insert geometry distributes loads evenly, reduces vibration, and stabilizes rotational motion. Optimized insert patterns ensure uniform wear, prevent stress concentrations, and contribute to longer operational life and consistent performance under demanding radial and axial loads.

Housing and Sealing Integration

Protective housings and seals prevent contamination, debris ingress, and moisture, maintaining clean operating conditions. Effective sealing reduces friction, corrosion, and lubricant loss, preserving performance, minimizing wear, and extending the operational life of TC Bearings in harsh industrial environments.

Thermal Management

Sintered TC Bearings dissipate heat efficiently, minimizing thermal expansion and deformation. Effective thermal management maintains dimensional stability, reduces overheating risks, ensures consistent rotation, and prolongs service life in high-speed, high-load, or continuous-duty applications.

Customization for Specific Applications

Tailored TC Bearing designs meet the operational demands of drilling motors, industrial machinery, and aerospace components. Custom geometry, material selection, and surface treatments optimize load capacity, durability, vibration resistance, and wear performance for specialized applications.

Best Practices for Extending TC Bearing Life

Installation Guidelines

Proper fitting, alignment, and seating prevent early bearing failure from misalignment or uneven load distribution. Following manufacturer specifications ensures optimal performance, reduces stress concentrations, minimizes vibration, and extends the service life of TC Bearings.

Monitoring Wear and Performance

Monitoring vibration, temperature, and noise provides critical insight into bearing condition. Early detection of wear patterns or abnormalities allows proactive maintenance, improves operational efficiency, prevents unscheduled downtime, and extends the bearing’s functional life.

Lubricant Selection and Application

Choosing lubricants compatible with operating conditions minimizes friction, heat, and wear. Optimized lubrication maintains consistent rotational performance, protects surface integrity, reduces energy consumption, and prolongs the service life of TC Bearings.

Regular Maintenance Schedules

Predictive maintenance, including inspections, lubrication, and timely component replacement, ensures uninterrupted performance. Regularly scheduled upkeep maximizes uptime, reduces failure risk, maintains operational efficiency, and extends the functional lifespan of bearings.

Future Trends in TC Bearing Technology

Material Innovations

Advanced carbide composites and nano-enhanced coatings improve hardness, toughness, and wear resistance. These material innovations extend service life, increase durability under extreme operational stresses, and enhance performance in high-load or abrasive environments.

Advanced Sintering Techniques

Refined sintering methods, including additive manufacturing integration, enhance particle bonding, microstructural uniformity, and hardness. These advancements improve TC radial bearing sintering process outcomes, yielding longer-lasting, more reliable, and high-performance bearings.

Smart Bearings

IoT-enabled bearings with integrated sensors allow real-time monitoring of vibration, load, and temperature. Predictive maintenance reduces unexpected downtime, increases operational efficiency, and extends bearing lifespan in critical industrial applications.

Sustainability Considerations

Longer-lasting TC Bearings reduce replacement frequency, material waste, and operational energy consumption. Investing in durable and efficient bearings supports environmental sustainability while maintaining high-performance and cost-effective industrial operations.

Conclusion

TC Bearings provide superior load capacity, durability, and efficiency. Optimized sintering, design, and materials enhance performance and service life. Weifang shengde petroleum machinery manufacturing co., LTD. offers tailored TC Bearings that ensure reliability and operational value.

FAQ

Q: What is a TC Bearing?

A: A TC Bearing is a tungsten carbide inlaid bearing designed for high-load and high-wear applications, offering durability improvements in TC bearings and long operational life.

Q: How does the TC radial bearing sintering process work?

A: The sintering process fuses carbide particles under heat and pressure, creating a dense surface that enhances wear resistance and extends the service life of TC bearings.

Q: Why choose Enhanced load capacity TC bearings?

A: They distribute loads evenly, reduce stress points, and improve reliability, ensuring extended service life of TC bearings in demanding environments.

Q: How do TC Bearings improve maintenance efficiency?

A: TC Bearings reduce wear and friction, enabling longer intervals between maintenance and lowering downtime, thanks to durability improvements in TC bearings.

Q: Are TC Bearings cost-effective compared to alternatives?

A: While initial costs may be higher, their extended service life and enhanced load capacity TC bearings provide better long-term value and operational efficiency.

Q: What factors affect the service life of TC Bearings?

A: Proper installation, optimized lubrication, and high-quality sintering determine the extended service life of TC bearings and overall durability.