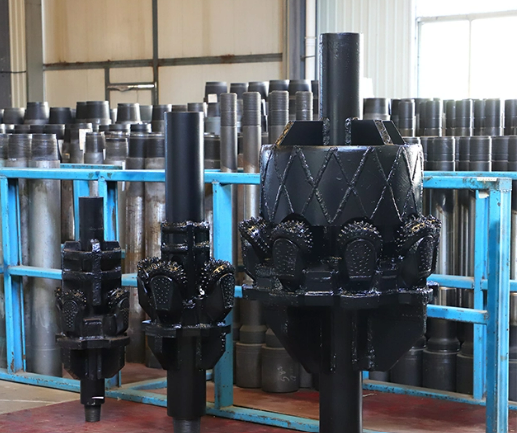

Choosing the right hole opener impacts speed, cost, and borehole quality. Engineers must decide between a HOB reamer and a cone reamer. Each excels in different formations and tasks. In this article, you will learn their differences, performance, and best hole opener for drilling strategies.

Core Differences Between HOB Reamer and Cone Reamer

Cutting Mechanism Comparison

The HOB reamer uses fixed blades to shear soft materials. Its blades slice through clay, sand, or soft shale efficiently. In contrast, the cone reamer features rotating cones that crush and grind harder rock layers. This difference affects penetration rates and borehole quality.

The shearing action of HOB reduces vibration in soft formations, while cone-type crushing adapts to irregular hard surfaces. They also differ in wear behavior, influencing maintenance schedules. Selecting the proper mechanism depends on the formation type and project priorities.

Formation Suitability

HOB reamers excel in soft formations, including clay, silt, and unconsolidated sand. They maintain borehole diameter while minimizing friction and torque. Cone-type reamers, however, are best for hard rock, granite, and limestone. Their robust design handles impact and abrasive conditions without major damage.

Mixed formations require careful evaluation. Soft layers favor HOB, while hard sequences require cone cutters. Engineers often alternate tools to balance efficiency and tool longevity.

Tool Durability and Maintenance

HOB reamers have fewer moving parts, reducing mechanical failure risks. Their fixed blades are easy to inspect and replace. Cone reamers, with rotating cones, demand regular lubrication and careful monitoring. Wear patterns differ: HOB blades wear on the edges, while cone teeth experience uniform abrasion.

Maintenance frequency also depends on formation hardness. Hard formations accelerate wear on HOB blades, while cones may require more preventive maintenance to avoid rotation issues.

Borehole Accuracy and Geometry

HOB reamers maintain consistet diameter in soft formations, minimizing deviation. Cone reamers provide precise boreholes in hard and mixed formations. Smooth cutting reduces the risk of casing misalignment. Accuracy directly affects project efficiency, preventing delays during installation.

![hole opener, HOB reamer, cone reamer hole opener, HOB reamer, cone reamer]()

Performance Analysis Across Formation Types

Soft Formation Performance

In soft soils, HOB reamers achieve higher penetration rates. They shear material without generating excessive vibration. Cone reamers may underperform in these conditions, often causing irregular hole surfaces.

Operators should consider soil cohesiveness and moisture content. HOB reamers generally outperform cones in unconsolidated sand and clay. Using the correct opener improves efficiency and reduces energy consumption.

Hard Formation Performance

Cone reamers dominate in dense rock and abrasive layers. Their crushing teeth penetrate granite and limestone effectively. HOB reamers in these formations experience rapid blade wear and slow penetration.

Operational strategies often pair cone reamers with optimized drilling fluids to reduce friction and extend tool life. Monitoring penetration rates helps engineers decide when to rotate or replace tools.

Formation Type | HOB Reamer Performance | Cone Reamer Performance |

Soft clay / sand | High penetration | Moderate penetration |

Hard limestone / granite | Low penetration | High penetration |

Mixed layers | Moderate | High adaptability |

Mixed Formation Handling

Projects with alternating soft and hard layers benefit from hybrid strategies. Engineers may start with HOB for soft layers and switch to cone reamers for hard rock. This approach maximizes efficiency while reducing tool wear. Case studies in HDD and mining demonstrate significant time savings when alternating openers based on formation type.

Cost Implications and ROI

Initial Investment

HOB reamers are generally less expensive than cone reamers. Their simple design reduces material and manufacturing costs. Cone reamers are costlier due to rotating cones, high-strength alloys, and complex assembly.

Operational Costs

Maintenance frequency, tool replacement, and downtime affect operational costs. HOB reamers in soft formations incur minimal expenses. Cone reamers, while durable in hard formations, require more preventive maintenance. Operational costs must be weighed against project complexity and formation hardness.

Long-Term ROI

Evaluating tool performance over time highlights ROI differences. HOB reamers save money in soft formations due to high efficiency and low maintenance. Cone reamers provide long-term benefits in hard formations where tool longevity prevents costly downtime. Selecting the right opener ensures cost-effectiveness across diverse projects.

Tool Type | Avg. Lifespan | Maintenance Cost | ROI Impact |

HOB Reamer | Moderate | Low | High in soft formations |

Cone Reamer | High | Moderate | High in hard formations |

Application Scenarios for Hole Openers

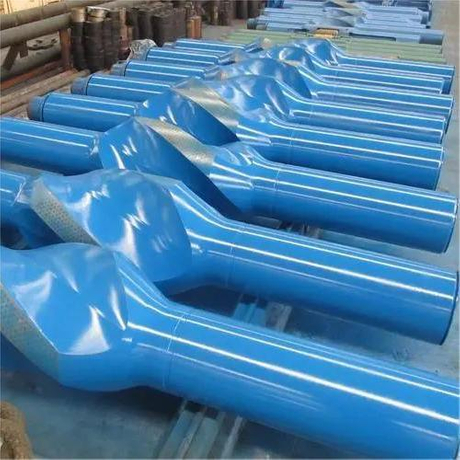

Horizontal Directional Drilling (HDD)

HDD projects benefit from tool selection based on soil conditions. HOB reamers advance efficiently in soft layers, reducing energy and time. Cone reamers maintain borehole consistency in mixed soils. Proper selection prevents downtime and enhances directional control.

Mining and Quarry Operations

HOB reamers remove soft overburden efficiently, lowering extraction costs. Cone reamers are ideal for tunneling through dense rock, offering durability and accurate borehole geometry. Engineers must evaluate layer thickness and hardness before selecting tools.

Water Well and Oilfield Drilling

Shallow wells in soft sediment favor HOB reamers for speed and cost-effectiveness. Deep wells with hard formations require cone reamers for durability. Borehole accuracy affects pump installation and long-term well performance.

Infrastructure Projects (Trenchless Drilling)

Hybrid approaches optimize performance. Alternating HOB and cone reamers ensures minimal vibration and precise hole geometry. Projects benefit from reduced downtime and improved project timelines.

Technological Innovations and Enhancements

Advanced Blade and Cutter Materials

Modern HOB blades now utilize tungsten carbide and ceramic coatings to enhance wear resistance and cutting efficiency. These materials allow the blades to maintain sharpness over longer drilling periods, even in abrasive soft formations. Cone reamers incorporate high-strength alloys to endure continuous crushing in hard rock. Such material improvements significantly extend tool life and reduce operational downtime, directly impacting project efficiency and cost-effectiveness.

Sensor Integration and Smart Drilling

Embedded sensors in hole openers provide real-time monitoring of wear, vibration, and overall performance. Engineers can track tool condition remotely, allowing timely maintenance before critical failures occur. This predictive maintenance minimizes unplanned downtime and avoids costly project delays. Integrating smart drilling technologies ensures more accurate drilling performance while extending the life of both HOB and cone reamers in demanding environments.

Hybrid Designs

Hybrid hole openers combine the fixed-blade design of HOB reamers with the rotating cones of cone reamers, offering versatile performance in mixed formations. Recent field trials demonstrate notable reductions in drilling time and tool wear when alternating cutting mechanisms are employed. These hybrid tools are particularly effective in HDD and complex oilfield projects. By adapting to variable formations, they provide both efficiency in soft layers and durability in hard rock.

Selection Guidelines for Engineers

Assessing Formation Conditions

Proper assessment of soil and rock conditions is crucial for selecting the optimal hole opener. Engineers should evaluate hardness, abrasiveness, and moisture content to ensure tool compatibility. Choosing the correct opener reduces wear, improves penetration rates, and maintains consistent borehole geometry. Accurate pre-drilling surveys prevent unnecessary tool replacements and enhance overall project efficiency.

Drilling Objectives and Priorities

Selection should balance speed, durability, and borehole precision. HOB reamers excel in soft formations where fast progress is needed, while cone reamers are essential for stability and accuracy in hard or mixed layers. Engineers must align tool choice with project goals to optimize performance. This ensures that both operational efficiency and borehole quality meet project requirements.

Project Budget Considerations

Evaluating upfront investment against operational efficiency is essential. HOB reamers offer cost savings in soft layers due to reduced wear and faster drilling. Cone reamers, while initially more expensive, prevent costly downtime in hard formations. Decision-making should consider total project cost, including maintenance, tool replacement, and operational performance over time.

Maintenance Planning

Regular inspections and proactive maintenance extend the life of both HOB and cone reamers. Engineers should schedule tool replacements based on formation hardness and project duration to minimize downtime. Proper lubrication and monitoring of wear patterns prevent unexpected failures. Effective maintenance planning ensures consistent drilling performance and protects overall project timelines.

Common Mistakes and How to Avoid Them

Misjudging Formation Hardness

Incorrectly assessing formation hardness can lead to rapid tool wear and reduced efficiency. HOB reamers struggle in hard rock, while cone reamers may underperform in soft soils. Conducting thorough pre-drilling surveys ensures accurate formation characterization. Proper evaluation prevents costly tool replacements and maintains consistent borehole quality.

Ignoring Maintenance Needs

Neglecting preventive maintenance shortens tool life and increases the risk of downtime. Regular inspection, cleaning, and lubrication are essential for both HOB and cone reamers. Planning maintenance according to formation type and project duration enhances operational efficiency. Staying proactive reduces unplanned interruptions and extends the productivity of drilling tools.

Overlooking Hybrid Strategies

Many projects benefit from alternating or combining HOB and cone reamers in mixed formations. Ignoring hybrid strategies can compromise efficiency and borehole consistency. Utilizing hybrid designs allows operators to optimize performance across soft and hard layers. Implementing this approach improves penetration rates, reduces wear, and ensures smooth completion of complex drilling projects.

Conclusion

Choosing the right hole opener depends on formation type and project goals. HOB reamers excel in soft soils with fast progress and low maintenance. Cone reamers ensure durability and precision in hard rock and mixed formations. Weifang shengde petroleum machinery manufacturing co., LTD. offers high-quality hole openers that enhance drilling efficiency, reduce costs, and maintain borehole accuracy across diverse projects.

FAQ

Q: What is the difference between a HOB reamer and a cone reamer?

A: A HOB reamer uses fixed blades to shear soft formations like clay and sand, offering fast drilling and low maintenance. A cone reamer has rotating cones that crush hard rock, providing durability and precision. Selecting the right hole opener ensures efficiency and borehole accuracy.

Q: How do I select the best hole opener for drilling?

A: Assess formation hardness, drilling depth, and project goals. Choose a HOB reamer for soft soils or shallow wells and a cone reamer for hard rock or deep drilling. This approach maximizes penetration rate, reduces tool wear, and maintains consistent boreholes.

Q: Why does borehole accuracy vary between HOB and cone openers?

A: HOB reamers maintain stable diameters in soft formations, minimizing deviation. Cone reamers handle hard or mixed layers efficiently, reducing vibration and ensuring smooth boreholes. Proper selection prevents casing issues and costly rework.

Q: Are HOB reamers cheaper than cone reamers?

A: HOB reamers have lower upfront costs and require less maintenance in soft formations. Cone reamers are more expensive initially but offer better long-term ROI in hard rock due to durability and reduced replacement frequency.

Q: Can I use a hybrid approach with hole openers?

A: Yes, alternating or combining HOB and cone reamers in mixed formations improves efficiency and extends tool life. This hybrid strategy balances speed, precision, and wear reduction, making it one of the best hole opener for drilling solutions.