Ever wondered why some offshore motors fail fast in harsh seawater mud? PDM mud motors face corrosion, wear, and temperature challenges that reduce their service life. In this article, we explore key selection criteria and protection strategies. You will learn how to enhance PDM reliability and extend motor life effectively.

Understanding the Challenges of PDM Mud Motors in Seawater Mud

Harsh chemical and electrochemical conditions in seawater mud

Seawater mud exposes PDM components to aggressive chemical and electrochemical reactions. Oxygen and dissolved salts create localized corrosion cells on metal surfaces, accelerating material loss. Over time, these reactions can weaken critical components, leading to unexpected failures. Understanding these conditions helps engineers choose materials and protective strategies that improve seawater mud motor durability.

Impact of salinity, oxygen gradients, and temperature on tool life

Salinity, oxygen concentration gradients, and temperature fluctuations interact to degrade PDM performance. High salinity increases corrosion rates, while oxygen gradients encourage pitting. Temperature changes can affect elastomer flexibility, bearing lubrication, and metal expansion. These factors collectively reduce tool life and compromise drilling efficiency.

Interaction between corrosion, erosion, and mechanical wear

Corrosion rarely occurs alone in seawater mud. Erosion from abrasive particles combines with chemical degradation to accelerate damage. The rotor and stator surfaces experience both mechanical wear and corrosion, which amplifies performance loss over time. Designing for dual damage mitigation is essential.

Table 1: Impact of Seawater Mud Factors on PDM Components

Factor | Effect on PDM | Severity |

Salinity | Accelerates pitting | High |

Oxygen gradients | Promotes uniform corrosion | Medium |

Temperature fluctuations | Elastomer degradation | Medium |

Abrasive particles | Rotor/stator erosion | High |

Key Criteria for PDM Mud Motor Selection

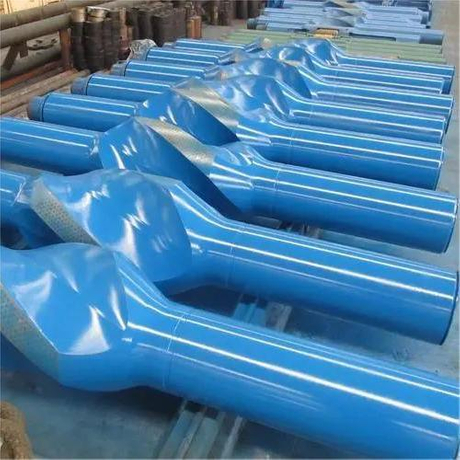

Matching rotor/stator design to torque and speed requirements

Selecting the correct rotor and stator geometry ensures the motor meets torque and speed demands. Improper matching can cause excessive wear, lower efficiency, and higher energy consumption. Optimizing design parameters also supports optimized PDM motor performance for corrosive mud.

Selecting elastomers resistant to saline and abrasive drilling fluids

Elastomers in PDM motors must resist chemical degradation and abrasive wear. Specialty compounds designed for saline and high-solid muds maintain sealing and flexibility. This selection improves overall reliability and extends maintenance intervals.

Bearing and seal configuration for improved reliability

Bearings and seals prevent mud ingress while supporting rotational loads. Configurations that handle pressure spikes, abrasion, and chemical attack enhance motor longevity. Choosing robust seal systems is crucial for seawater mud motor durability.

Flow rate and pressure drop considerations in seawater mud

Flow rate affects rotor efficiency and wear patterns. Maintaining optimal flow minimizes erosion and pressure-related stress while achieving desired rate of penetration (ROP). Pressure drop across the motor must also be balanced for effective performance.

Balancing performance needs with tool longevity

High-speed or high-torque demands often trade off against component life. Engineers must balance operational performance with durability to avoid frequent failures. Thoughtful selection of all components ensures long-term success.

![PDM mud motor PDM mud motor]()

Corrosion Mechanisms in Seawater Mud Environments

Formation of oxygen concentration cells at seawater–mud–air interfaces

At mud-air interfaces, oxygen concentration differences create localized corrosion cells. These cells accelerate pitting on exposed metal surfaces, particularly at edges and welds. Understanding these zones allows targeted protection.

Electrochemical reactions leading to pitting and uniform corrosion

Electrochemical reactions in seawater mud can cause both pitting and uniform corrosion. Pitting is localized and aggressive, while uniform corrosion slowly thins metal surfaces. Together, they reduce structural integrity and motor efficiency.

Time-dependent evolution of corrosion products (red rust vs black rust)

Corrosion evolves over time, producing visible red or black rust depending on oxygen availability and chemical composition. Red rust generally indicates ongoing oxidation, while black rust may indicate passive layers forming. Both types must be considered in maintenance planning.

How seawater mud accelerates dual damage: wear + corrosion

Seawater mud not only corrodes but also erodes PDM surfaces. Abrasive solids scrape metal and elastomers while chemical reactions weaken structures. Dual damage accelerates wear and shortens tool life.

Material Selection for Corrosion Resistance

Benefits of corrosion-resistant alloys (CRAs) in PDM components

CRAs like duplex stainless steel and nickel alloys resist chemical attack while providing mechanical strength. These alloys reduce pitting and uniform corrosion, improving motor lifespan.

Role of duplex stainless steels, nickel alloys, and titanium

● Duplex stainless steels: Balanced strength and corrosion resistance.

● Nickel alloys: High pitting and crevice resistance.

● Titanium: Lightweight and extremely resistant to aggressive mud.

Using these materials in critical components enhances PDM technology for offshore oil well applications.

Coatings and surface treatments for external and internal protection

Ceramic, polymeric, and diamond-like coatings prevent direct exposure to seawater mud. Internal coatings protect fluid pathways, while external layers shield housing from abrasion. Proper coating selection reduces maintenance intervals and downtime.

Cost vs durability trade-offs when choosing high-performance materials

High-performance alloys increase initial costs but reduce frequency of repairs and replacements. Operators must consider both upfront investment and long-term savings when selecting materials.

Table 2: Material vs Performance in Seawater Mud

Material | Corrosion Resistance | Cost | Typical Application |

Duplex Stainless Steel | High | Medium | Rotor/Stator housing |

Nickel Alloys | Very High | High | Bearings, seals |

Titanium | Excellent | Very High | Critical structural parts |

Coated Carbon Steel | Medium | Low | Non-critical external parts |

Protective Strategies for PDM Mud Motors in Seawater Mud

Application of internal and external coatings (ceramic, polymeric, diamond-like)

Coatings, chemical inhibitors, and advanced seals work together to protect PDM mud motors in seawater mud. Internal and external coatings create a barrier that shields components from corrosive fluids, while chemical inhibitors neutralize aggressive ions in high-salinity environments. High-quality seals prevent mud from entering critical areas, accounting for pressure spikes and abrasion. Combined with routine inspections and scheduled maintenance, these strategies extend rotor and stator life, reduce downtime, and ensure an optimized PDM motor for corrosive mud operates reliably.

Operational Considerations During PDM Deployment

Optimizing flow rates and differential pressures to reduce stress

Maintaining correct flow rates prevents cavitation and reduces abrasive wear on rotor and stator surfaces. Monitoring differential pressure ensures the motor operates within safe limits, preventing overload or premature failure. Adjusting flow dynamically based on mud properties enhances performance. Proper flow management also supports consistent rate of penetration and reduces maintenance frequency.

Minimizing downtime through preventive inspections

Routine inspections detect early signs of wear, corrosion, or seal degradation before major failures occur. Preventive maintenance allows operators to schedule interventions efficiently, avoiding unscheduled downtime. Combining visual checks with condition monitoring ensures issues are caught early. This proactive approach extends motor life and maintains drilling efficiency.

Adjusting drilling parameters to balance ROP and tool wear

High rate of penetration (ROP) increases productivity but also stresses PDM components, especially rotor, stator, and seals. Balancing drilling speed and torque minimizes excessive wear and prevents overheating. Regularly fine-tuning parameters ensures consistent performance without sacrificing longevity. It also reduces the likelihood of costly repairs or downtime during operations.

Training crews on handling and storing PDMs in marine environments

Proper handling, cleaning, and storage of PDM mud motors prevent corrosion before deployment. Well-trained crews reduce human error, ensuring components remain protected during transport and on-site storage. Consistent handling practices maintain seal and elastomer integrity. Investing in crew training enhances operational safety and motor reliability.

Case Examples and Lessons Learned

Failure analysis of PDM mud motors exposed to high-salinity mud

Analysis of failed motors shows that high salinity often leads to pitting, accelerated wear, and premature seal failure. Recognizing these failure patterns helps engineers choose better materials and protective strategies. Understanding root causes prevents repeated mistakes. Lessons learned guide future motor selection and coating applications.

Success story: extended life through advanced coatings

Motors coated with ceramic or polymeric layers achieved 30-40% longer service life (verification needed). Coatings effectively mitigate both corrosion and erosion, reducing downtime. Operators observed more consistent performance across drilling runs. This demonstrates the tangible benefits of investing in protective surface treatments.

Material substitution results in reduced maintenance frequency

Replacing standard steel components with duplex stainless steel or nickel alloys significantly lowered maintenance intervals. High-performance materials resist corrosion and abrasive wear more effectively. Over time, this reduces operating costs and enhances reliability. Material upgrades prove especially valuable in high-salinity or abrasive mud conditions.

Common mistakes in PDM selection and how to avoid them

Common errors include underestimating corrosion risk, overlooking abrasive effects, and prioritizing speed over durability. These mistakes lead to early failures and increased operational costs. Proper evaluation of environmental conditions and motor specifications prevents such issues. Avoiding shortcuts ensures long-term efficiency and reliability.

Future Trends in PDM Selection and Protection

Innovations in elastomer and composite materials

Next-generation elastomers and composites offer superior chemical resistance and enhanced flexibility. They maintain sealing performance under high temperatures and saline environments. These materials reduce wear on rotor and stator components. Operators benefit from longer maintenance cycles and improved motor durability.

Smart coatings with self-healing or anti-fouling properties

Self-healing and anti-fouling coatings automatically repair minor surface damage and prevent biofouling. This reduces the need for frequent maintenance and limits downtime. Such coatings extend service life in harsh marine environments. They also protect critical internal and external components from chemical attack.

Digital monitoring of corrosion and wear in real time

Embedded sensors track corrosion, wear, and operational stress continuously. Real-time monitoring enables predictive maintenance and early interventions. This reduces unexpected failures and maximizes tool availability. Operators gain insights to optimize drilling parameters and extend motor life.

Sustainability: reducing chemical inhibitors and environmental footprint

Advanced materials and coatings reduce reliance on chemical inhibitors, lowering environmental impact. Sustainable strategies maintain motor performance without compromising protection. Operators can meet environmental regulations while improving operational efficiency. Green solutions support long-term offshore drilling sustainability.

Conclusion

Selecting the right PDM mud motor is key for offshore drilling. Effective corrosion protection, proper materials, and coatings enhance reliability. Weifang shengde petroleum machinery manufacturing co., LTD. offers advanced PDM mud motors that extend service life and optimize performance. Their products provide durability and efficiency, delivering clear value for marine drilling operations.

FAQ

Q: What is a PDM mud motor?

A: A PDM mud motor drives drilling tools in seawater mud. It improves PDM reliability in marine drilling operations and resists corrosion.

Q: How can I protect a PDM mud motor from seawater corrosion?

A: Using coatings, chemical inhibitors, and high-performance materials enhances seawater mud motor durability and extends service life.

Q: Why is rotor/stator design important for PDM motors?

A: Matching rotor/stator design ensures torque and speed efficiency, optimizing PDM motor for corrosive mud performance.

Q: What are the benefits of high-end PDM mud motors?

A: They offer longer life, reduced maintenance, and enhanced PDM technology for offshore oil well applications.

Q: How do I maintain a PDM mud motor during offshore drilling?

A: Regular inspections, flow optimization, and crew training prevent wear and corrosion, ensuring optimized PDM motor for corrosive mud.