Global standards for drilling jar production give clear rules for quality and performance. These standards help make drilling more reliable. They also help every project run better. The market for drilling jars is getting bigger. This shows that people need products that follow the rules:

Year | Market Size (USD Billion) | CAGR (%) |

2024 | 1.62 | 3.76 |

2035 | 2.432 | N/A |

If you pick a drilling jar that meets ISO or API standards, you get many benefits. It works better with other equipment. It is easier to use with other tools. It also makes work safer. Shengde is a leader in this field. They do even more than what the standards ask. This helps you make your oilfield work better. Knowing about the different standards, types, and models helps you pick the best tool for your drilling job.

Key Takeaways

Global standards for drilling jars help keep people safe. They also make drilling projects work better and faster.

Picking a drilling jar with API or ISO standards helps it fit with other tools. It also makes the job safer.

Knowing about different drilling jars, like hydraulic and mechanical, helps you pick the best one for your job.

Always check the certification papers for drilling jars. This makes sure they are safe and good quality before you use them.

Choosing the right drilling jar model depends on things like how much pull it can take and how deep you will drill. This can help your drilling work a lot.

Drilling Jar Standards Overview

What Is a Drilling Jar?

A drilling jar helps when pipes or tools get stuck. It gives a strong hit up or down to free the equipment. The tool has a sliding mandrel and a part that stores energy. This energy is released all at once. These things make the tool very important for oilfield work. They help keep drilling jobs running well.

There are many kinds of drilling jars. Some are hydraulic jars. These use fluid to control when and how hard they hit. Others are mechanical jars. These work by building up tension or compression before they work. There are also active and passive jars. Each type has special features for different drilling jobs.

Function/Principle | Description |

Impact Generation | Drilling jars give a strong hit up or down to free stuck pipes or tools. |

Mechanism | They use a sliding mandrel to give a sudden force. |

Hydraulic Operation | Hydraulic jars use fluid to control when and how hard they hit. |

Mechanical Activation | Mechanical jars work at set tension or compression levels. |

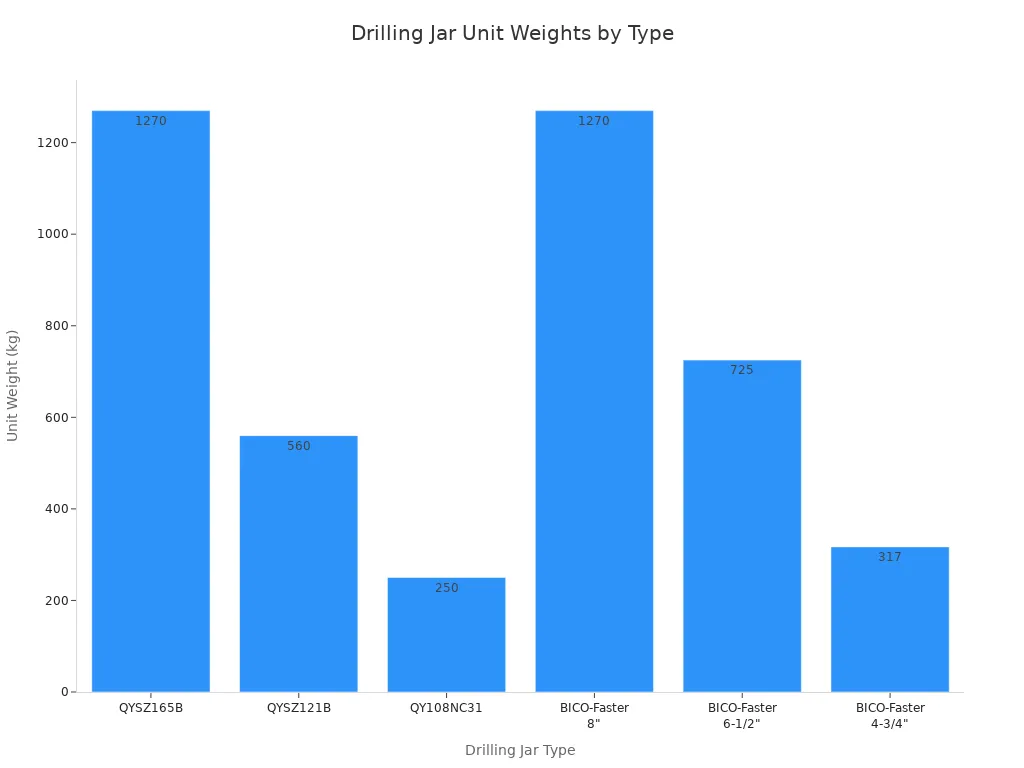

You can see that each drilling jar type has its own features. Here is a chart that shows the weights of different models:

Why Standards Matter

Standards are very important for making drilling jars. They help make sure the tools are safe and work well. If you pick a drilling jar that meets global standards, it will fit with other tools. It will also work in hard drilling jobs.

There are different groups of standards. Some are for protecting the environment. Others are for design and testing. Here is a table with some important standards:

Standard Code | Description |

API RP 75L | Gives rules for safe and green drilling. |

API RP 51R | Gives rules for protecting the land in oil and gas work. |

API Spec 16D | Tells how to design and test blowout preventer systems. |

API Spec 17D | Gives rules for subsea production systems and equipment. |

These standards help make sure every part of the drilling jar is good. They also help you compare different jars and their features. This makes it easier to pick the right tool. It also helps make sure your drilling job goes well every time.

Key International Standards

API Standards for Drilling Jars

The American Petroleum Institute, or API, makes important rules for drilling jar production. These rules focus on safety, quality, and how well the tool works. If your drilling jar meets API standards, you can trust it in your bha. API Spec 7 is a main rule for drilling jars. It talks about what materials to use, how to design, and how to test the jars. This helps your bha work well, even in hard jobs. API standards also help your drilling jar fit with other bha tools. This makes designing your bha easier and better.

Shengde follows API rules very closely. They test every drilling jar to make sure it meets or goes beyond these rules. This helps you feel safe and sure when you use their drilling jar in your bha.

ISO and ASTM Standards

ISO and ASTM are two big groups that make rules for drilling jar production. ISO rules come from teams that work on drilling equipment, well control, and wellhead systems. ASTM rules help decide what materials to use and how to test them. These rules make sure your drilling jar fits in any bha and works safely in many places.

Here is a table that shows some ISO working groups for making drilling jars:

Reference | Title | Type |

ISO/TC 67/SC 4/WG 1 | Drilling equipment | Working group |

ISO/TC 67/SC 4/WG 2 | Drilling well control equipment | Working group |

ISO/TC 67/SC 4/WG 3 | Wellhead and Christmas tree equipment | Working group |

ASTM rules focus on what your drilling jar is made of. They help you pick a jar for your bha that is strong and lasts long. ISO 9001 is a common rule for checking quality in drilling jars. ASTM rules also help you compare different drilling jars for your bha.

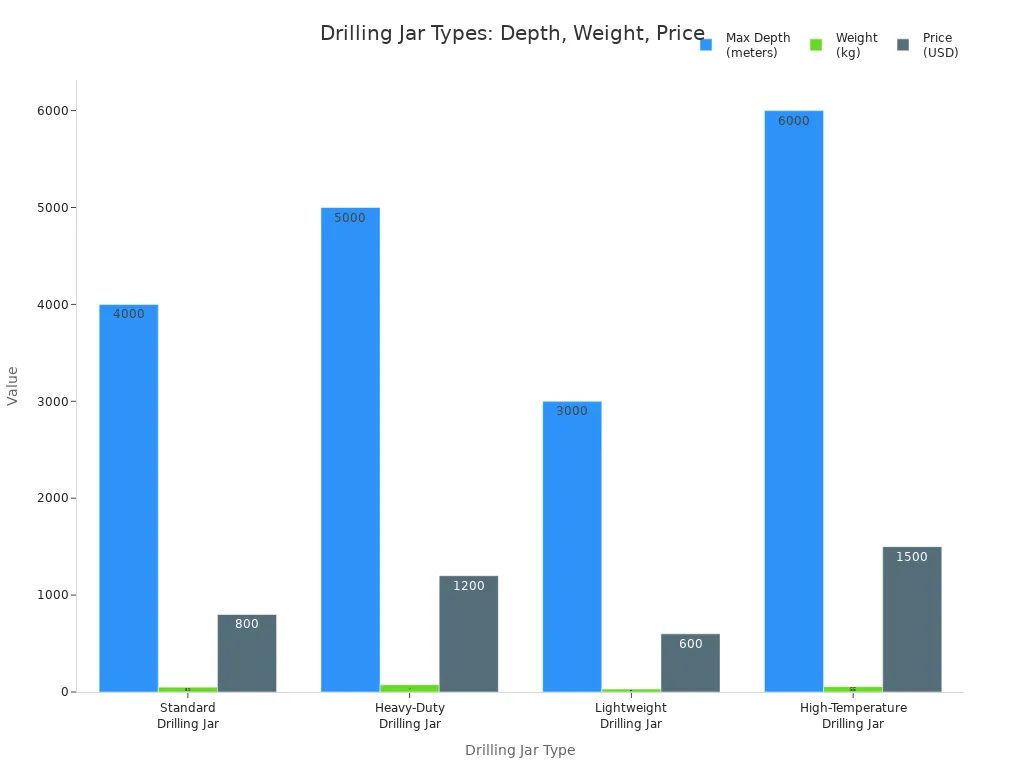

You can see how these rules change the material, depth, and weight of each drilling jar in this table:

Drilling Jar Type | Material | Max Depth (meters) | Weight (kg) | Price (USD) | Quality Assurance Standard |

Standard Drilling Jar | Steel | 4000 | 50 | 800 | ISO 9001 |

Heavy-Duty Drilling Jar | Alloy Steel | 5000 | 75 | 1200 | API Spec 7 |

Lightweight Drilling Jar | Aluminum | 3000 | 30 | 600 | ASTM Standards |

High-Temperature Drilling Jar | Heat-Resistant Steel | 6000 | 55 | 1500 | NPT Standard |

When you pick a drilling jar for your bha, these rules help you choose the right one. This helps your oilfield work better and keeps your bha safe.

Regional and NPT Standards

Regional rules are also important when you pick a drilling jar for your bha. NPT rules are used a lot in the US and Canada. These rules make sure threads fit well and do not leak. The GB/T12716-1991 rule gives clear details for NPT thread size, shape, and fit. This helps you stop problems with your bha while drilling.

Here is a table that compares NPT and BSP threads:

Feature | NPT (National Pipe Thread) | BSP (British Standard Pipe) |

Thread Angle | 60 degrees | 55 degrees |

Thread Form | Flat peaks and valleys | Rounded crests and roots |

Taper Rate | 1:16 | N/A |

Standards Compliance | ASME B1.20.1 | ISO 7/1, BS 21 |

Usage Region | Predominantly US and Canada | UK, Europe, Asia, Australia |

NPT threads are mostly used in the US and Canada. BSP threads are common in the UK, Europe, and other places.

NPT threads need sealants to stop leaks. BSP threads may or may not need sealants, depending on the type.

When you build your bha, you must check which thread type is right for your area. This helps you stop leaks and keeps your drilling jar working well in your bha.

Comparison of API, ISO, and ASTM Standards

You might wonder how these rules are different. API rules are for oil and gas jobs, especially for bha tools like the drilling jar. ISO rules are for quality and safety all over the world. They help your bha work in many countries. ASTM rules are about testing materials and how well they work. They help you pick the best drilling jar for your bha.

Standard | Focus Area | Main Benefit for BHA |

API | Oil and gas, bha tools | High reliability and safety |

ISO | Global quality, safety | Works in many regions |

ASTM | Material testing | Strong and durable bha tools |

How Shengde Aligns with International Standards

Shengde makes sure every drilling jar meets top rules. The company has ISO9001:2015 for quality, ISO45001:2018 for safety, and ISO14001 for caring for the environment. Shengde also follows API rules for drilling jars. You can see their certificates in this table:

Certification Type | Year | Description |

ISO9001:2015 | 2015 | Quality management system certification |

ISO45001:2018 | 2018 | Occupational health and safety management system |

ISO14001 | N/A | Environmental management system |

API | N/A | American Petroleum Institute standards compliance |

Shengde uses a strong system to check quality. They test every drilling jar for safety and how well it works. You can trust each drilling jar to work well in your bha and help you finish your drilling job.

Groups like IOGP and IRF also help make these rules. They work together to make sure your drilling jar and bha meet the best safety and quality rules. This teamwork helps you get great results in your drilling projects.

Ensuring Quality and Performance

Material and Design Requirements

You need a strong drilling jar for your oilfield work. The material and design decide how well it works. Good drilling jars use metals like alloy steel or heat-resistant steel. These metals help the tool last longer in hard jobs. The design must let the drilling jar handle high pressure and big hits. You want a tool that stays strong after many uses.

Each group has its own rules for materials and design. Here is a table that shows what API, ISO, and ASTM want:

Standard | Material Requirement | Design Focus | Performance Target |

API | Alloy steel, tested for strength | Impact resistance, safety | Reliable operation in harsh drilling |

ISO | Certified metals, traceable source | Global compatibility | Consistent performance worldwide |

ASTM | Material purity, corrosion resistance | Durability | Long-lasting performance |

You should look at these rules before picking a drilling jar. This helps you get a tool that works well and lasts long.

Testing and Certification

Testing and certification check if your drilling jar is safe and strong. You want a tool that passes every test for safety and how it works. The tests look at the material, design, and how it works in real drilling. A certified drilling jar is safe and works well for your team.

Shengde uses a good quality system to make sure you get the best tool. They check every step, from the start to the end. Here is how they check quality:

Stage of Quality Control | Description |

Incoming Quality Control (IQC) | Inspection of all raw materials before production |

Input Process Quality Control (IPQC) | Patrol inspection during each production step |

Quality Control (QC) | Full inspection of finished products before packaging |

Outgoing Quality Control (OQC) | Final inspection before shipment |

You get a strong and good drilling jar that meets or beats the rules. This helps you avoid problems and keeps your drilling job going well.

Tip: Always ask for testing and certification papers before you buy. This helps you make sure you get drilling jars that work well.

You make your oilfield work better by picking tools that meet strict rules. This gives you better results and helps your oilfield work smoother.

Compliance and Selection of Drilling Jar Models

Verifying Certification

You need to check if your drilling jar meets the right standards. Certification shows the tool is safe and works well. Always look for official papers like API, ISO, or ASTM certificates. These papers prove the maker follows strict rules for quality.

Here are some easy tips to help you check compliance:

Ask the supplier for the newest certification papers.

Make sure the certificates match your drilling jar model.

Look for testing and inspection details on the certificate.

Check that the certificate is from a trusted group.

You might run into some common problems when checking compliance. The table below shows what to watch for and how to avoid mistakes:

Common Pitfall | Explanation |

Not using the right steps long enough to activate the jar | This happens because people make mistakes, especially new crews. Make sure work instructions are clear and easy to find on the drill floor. |

Mechanical limits stop the jar from working | In long wells and wells with high angles, the drill string can bend and stop the jar. Know which parts of the well are risky before you start. |

The jar is not in the best spot for a strong hit | Good placement is important for jarring. Place the jar based on energy transfer, not just what is easy to handle. |

Tip: Always read the maker’s papers and ask questions if you do not understand something. This helps you avoid trouble and keeps your drilling job running well.

Choosing the Right Drilling Jar Model

You need to pick the right drilling jar for your drilling job. The right choice helps you work better and avoid problems downhole. You should look at some key things when picking a drilling jar.

Maximum Over Pull: This tells you how much force the jar can take before breaking. You need this for safe energy use.

Tensile Yield: This shows how much pulling the tool can handle. Make sure every part of your string can take the load.

Torsional Yield: This measures how well the jar resists twisting. It matters for wells with tough loads.

Think about how you use the drilling jar in your job:

Jar Placement: Put the jar where it gives the best energy transfer. Good placement helps the jar work better.

Depth and Formation Properties: Think about how deep the well is and what kind of rock you drill through. Some jars work better in certain rocks.

Hydraulic vs. Mechanical Jars: Hydraulic jars use fluid to control force. Mechanical jars use tension or compression. Pick the type that fits your drilling job.

Shengde gives clear model papers and good help. You can find easy charts and guides for each drilling jar model. The company helps you match the right jar to your drilling job. If you have questions, their team can help you choose the best jar for your drilling.

Note: Picking the right drilling jar makes your job safer and better. It also helps your drilling work go smoothly and be more productive.

Always use certified products and follow the maker’s advice. This helps you get the most from your drilling jar and keeps your drilling job on track.

Conclusion

You help keep drilling safe and running well. Global standards make it easier to trust each drilling jar. Certified products keep your team safe and save money. They do this by stopping stuck pipe problems and making work faster. Look at the table below to see the benefits:

Benefit | Explanation |

Insurance against stuck pipe | Stops delays and extra work that cost money |

Sharp hammer-like blows | Gets stuck tools out fast and safely |

Optimal performance | Helps you pick the best jar for each job |

You can see new things like smart jars and digital tracking. Companies such as Shengde offer certified and advanced tools. Keep learning and pick the right model for your drilling jobs.

FAQ

What is a drilling jar used for?

You use a drilling jar to free stuck pipes or tools during drilling. The tool gives a strong hit to help you keep your project moving forward.

How do you know if a drilling jar meets global standards?

You check for certificates like API, ISO, or ASTM. These papers show that your drilling jar passed important tests for safety and quality.

Why does material choice matter for drilling jars?

You need strong materials so your drilling jar can handle tough jobs. Alloy steel and heat-resistant steel help your tool last longer and work better.

How does a drilling jar improve efficiency in drilling operations?

You use a drilling jar to solve stuck pipe problems quickly. This tool helps you save time and keep your drilling job running smoothly.